Helical tooth plastic gears: why choose them.

23 April 2020

The use of precision plastic gears is increasing every day, and in various applications both resistance and, safe and silent operation are often required. Metal replacement activity guarantees the answer to both needs. Thanks to Stagnoli’s innovative proposal of helical tooth plastic gears, the performances related to reduced noise and smooth performance are amplified.

Plastic gears: the advantages of technopolymer components.

On a mechanical level, gears and components in plastic, compared to metal ones, have the ability to absorb vibrations. This is due to the intrinsic nature of technopolymers and plastics in general, which makes possible to dampen noise and therefore reduce the transmission of vibrations. This is often not enough, especially in those applications where silence is an essential condition. A typical example in this regard is the perceived comfort inside a vehicle which is determined by the so-called NVH (acronym of Noise-Vibration-Harshness) performance that the car can provide in different conditions: in acceleration at full power, on an uneven road, at constant speed on urban or suburban routes.

The high sensitivity of customers to comfort problems has been confirmed in recent years by the evidence that style and comfort prevail among the selection criteria for the purchase of a new car, together with quality and price, compared to other aspects such as performance and safety. For this reason, every detail that can reduce noise is taken into consideration by manufacturers in the automotive sector.

Plastic helical tooth gears for maximum noise reduction.

Stagnoli has strongly contributed to the request to reduce noise thanks to its know-how regarding the design and construction of plastic components. Its best contribution was in the field of technopolymer gears, a sector in which Stagnoli is the undisputed leader. In fact, among the gears, the direction taken was undoubtedly that of considering plastic materials, but what distinguished Stagnoli was the idea of designing and manufacturing helical tooth plastic gears, an upgrade, if you consider noiseless compared to straight tooth plastic gears.

Why do helical tooth plastic gears work better than straight tooth gears?

We focused on the continuity of transmission in a pair of gears. The essential condition for this to exist is that two engaged teeth do not completely leave before two other teeth have started to engage. In plastic straight-toothed gears it happens that the gripping pair of teeth abandons contact along the entire axial length of the crown, while, simultaneously, the next pair of teeth that is entering the engagement starts the contact along the entire axial length. This gives rise to vibrations and noises. In helical tooth gears, the gripping teeth are gradually released, and in the same way the subsequent teeth begin to engage gradually: the transmission of motion is silent, regular, without shocks or vibrations. The thrust surface between the teeth is greater and the contact occurs more gently, eliminating the characteristic screeching of the straight tooth gears.

The advantages of helical tooth plastic gears.

The main benefits of using helical tooth gears compared to straight tooth gears are:

- smoother operation with reduced friction

- possibility to bear a greater load

- low noise and noticeable reduction of vibrations

A helical couple that engages also has a greater contact ratio than the corresponding spur gear. The frictional forces generated by the mutual sliding of the teeth before and after the primitive point are significantly reduced.

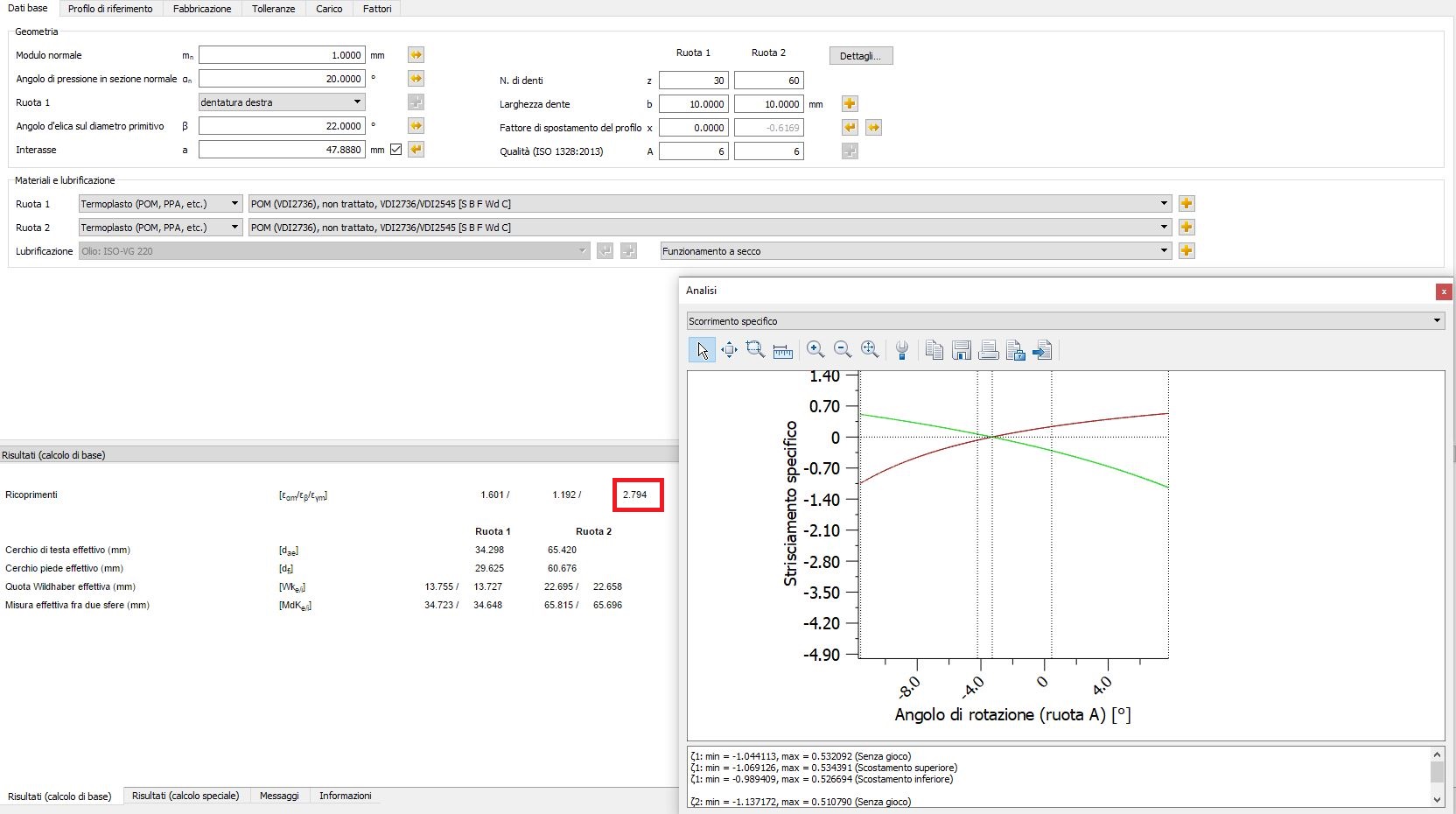

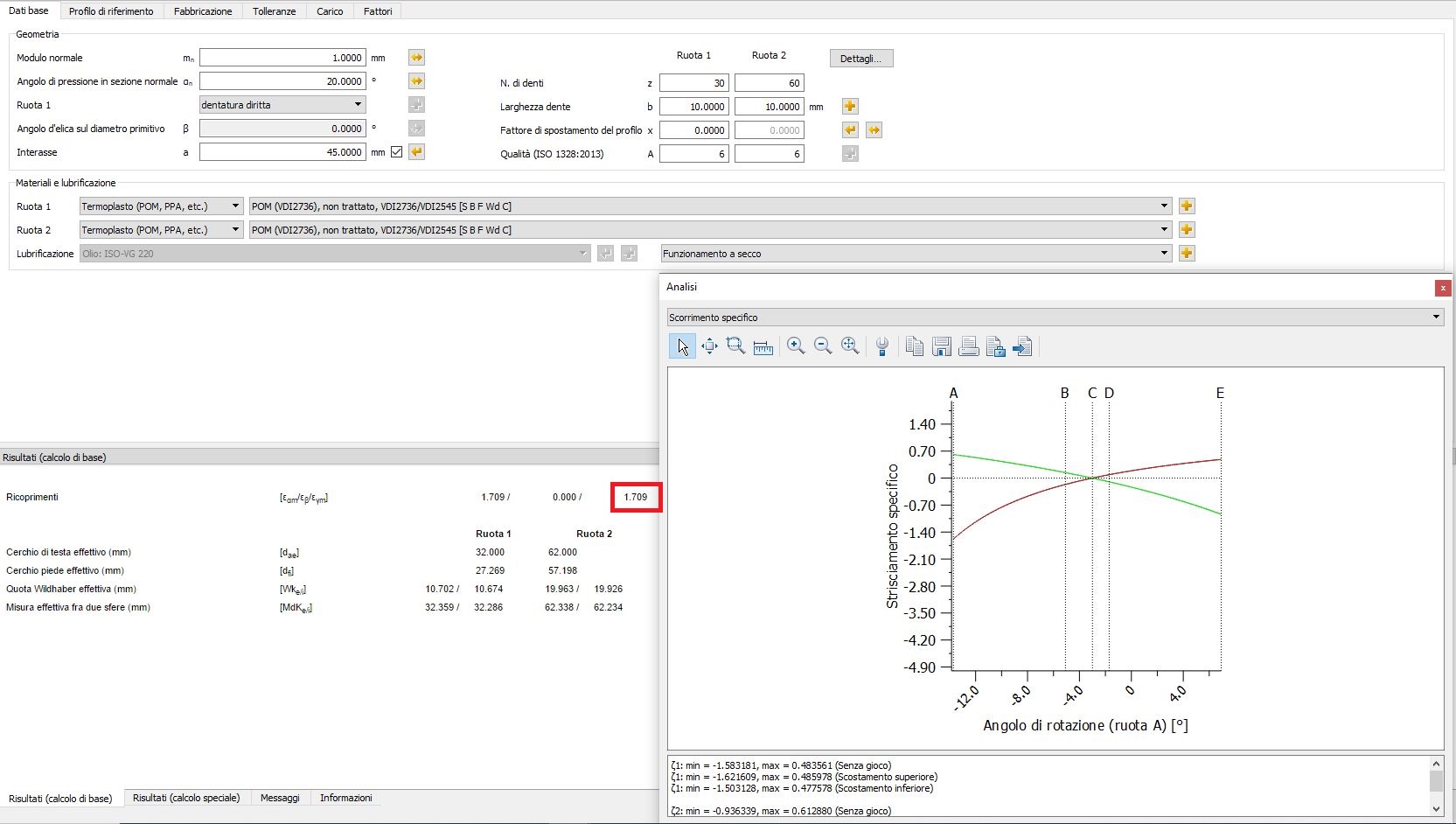

In this regard, in the images below we report the calculation of the covering and the trend of the specific sliding in a pair of straight-toothed gears and a pair of helical-toothed gears, keeping the geometry constant, i. e. module, number of teeth and pressure angle.

Fig. 1 Straight-toothed gears

Fig. 2 Helical-toothed gears

It is clearly noted that in the pair of helical tooth gears (fig. 2) the covering increases and the specific sliding decreases which takes into account the friction forces developed during the engagement.

Do you want to speak with our team of technicians to design together the plastic gears that improve the performance of your machinery? Contact Stagnoli.