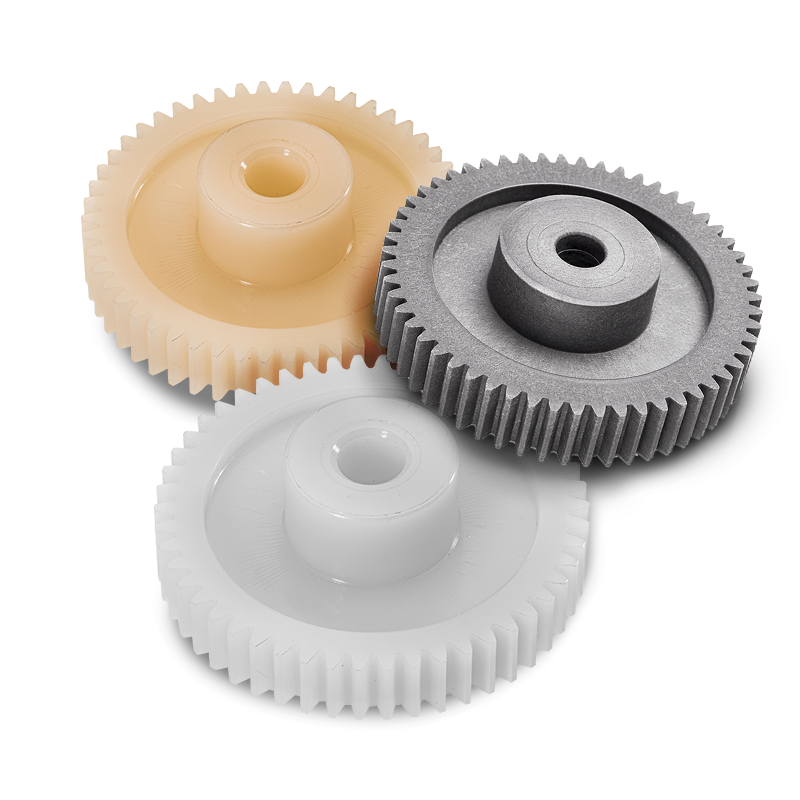

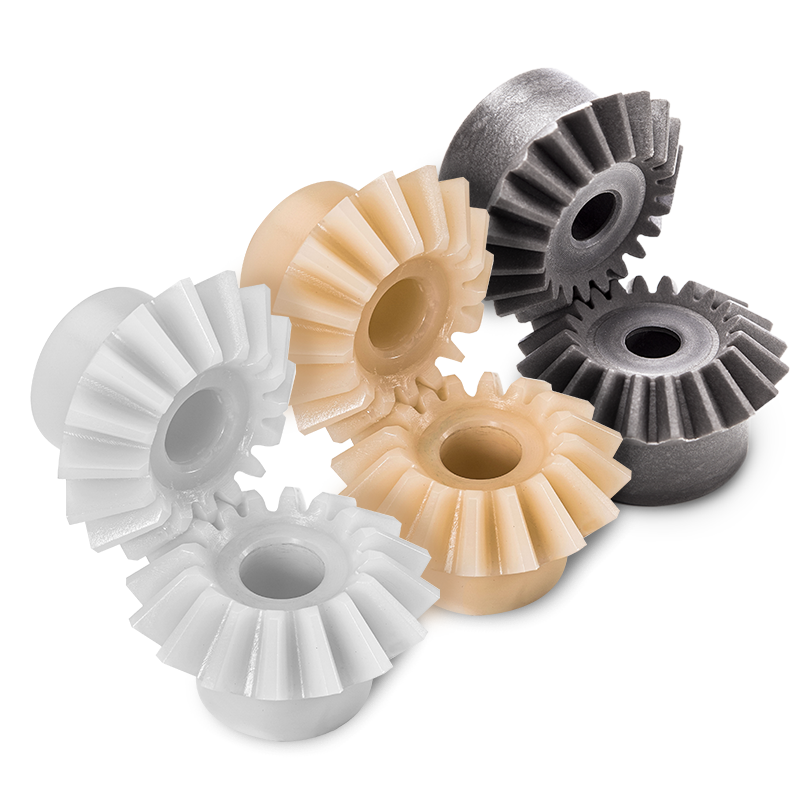

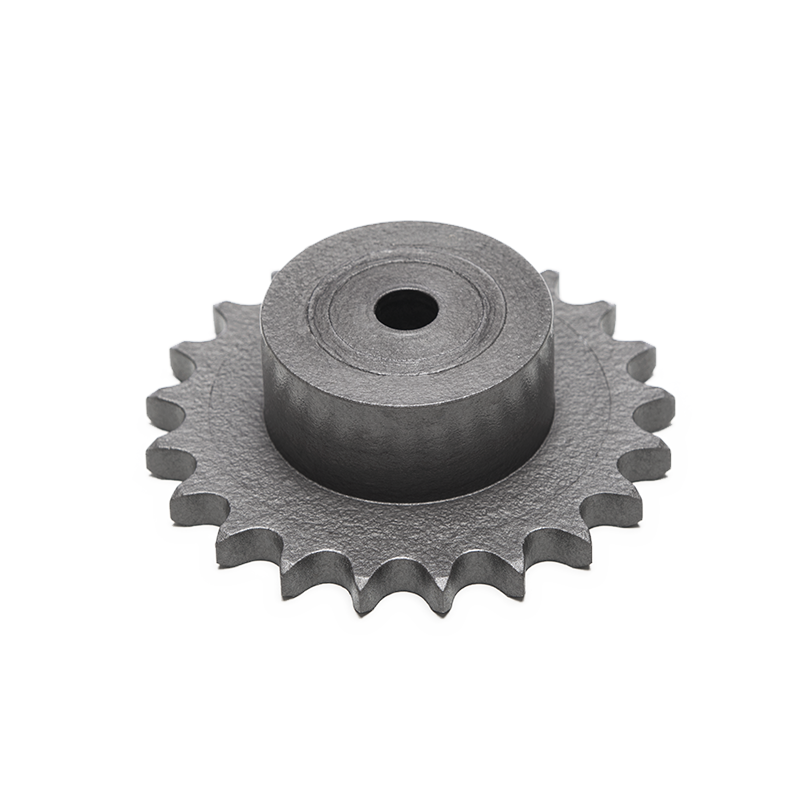

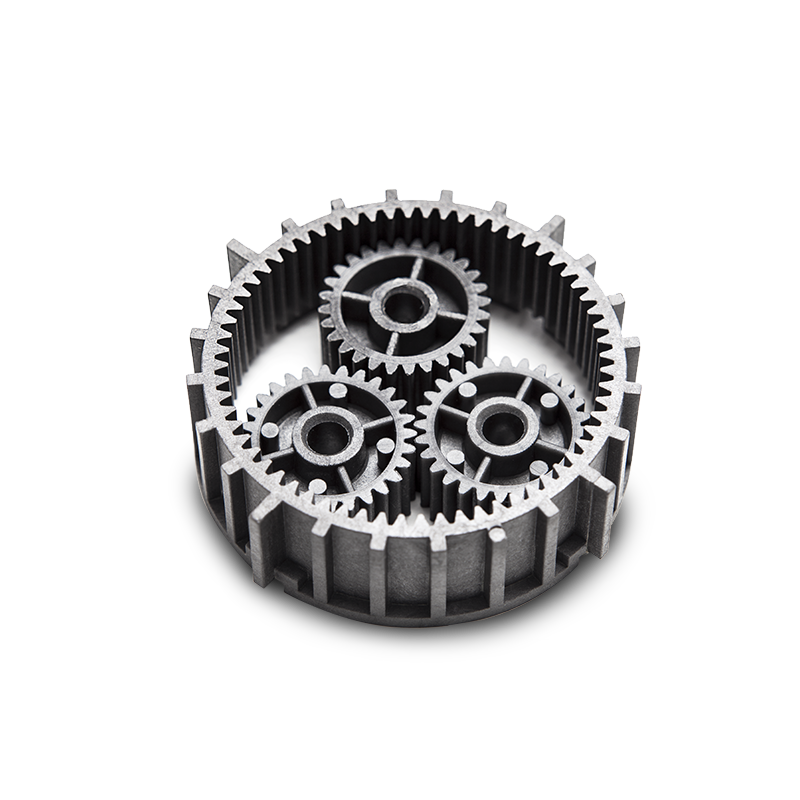

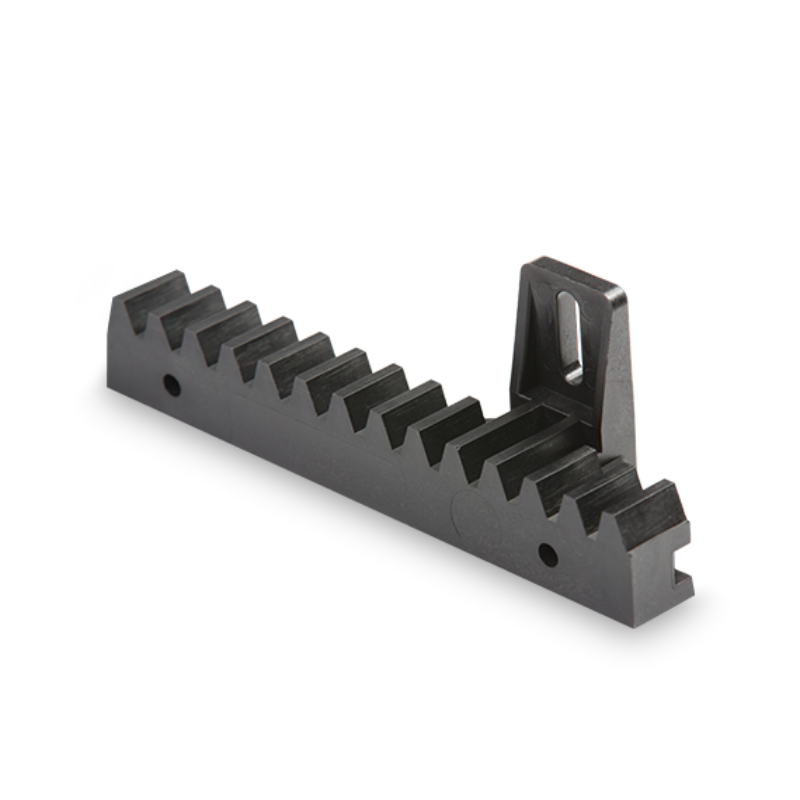

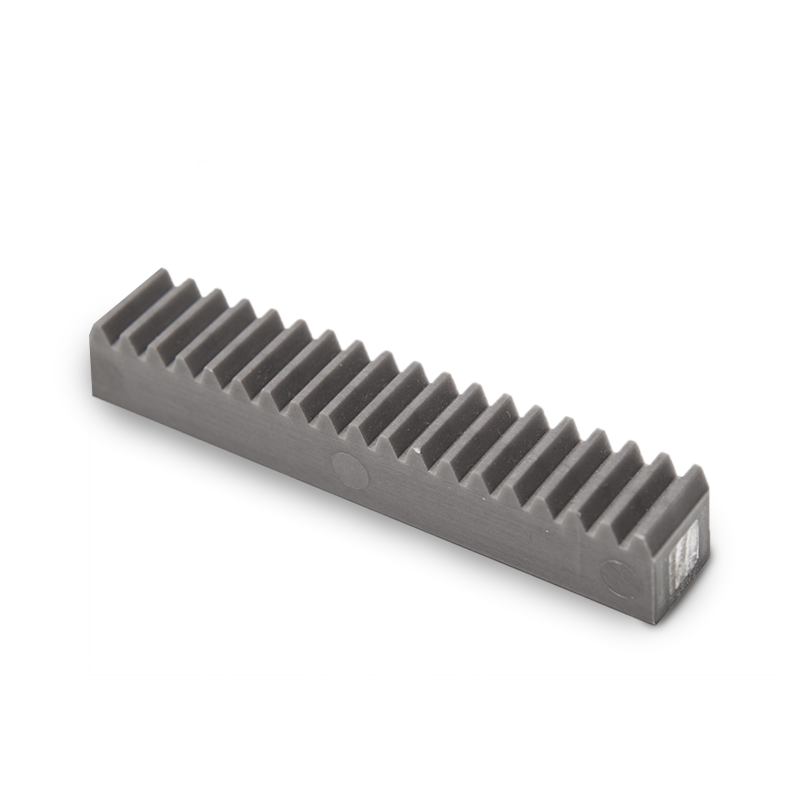

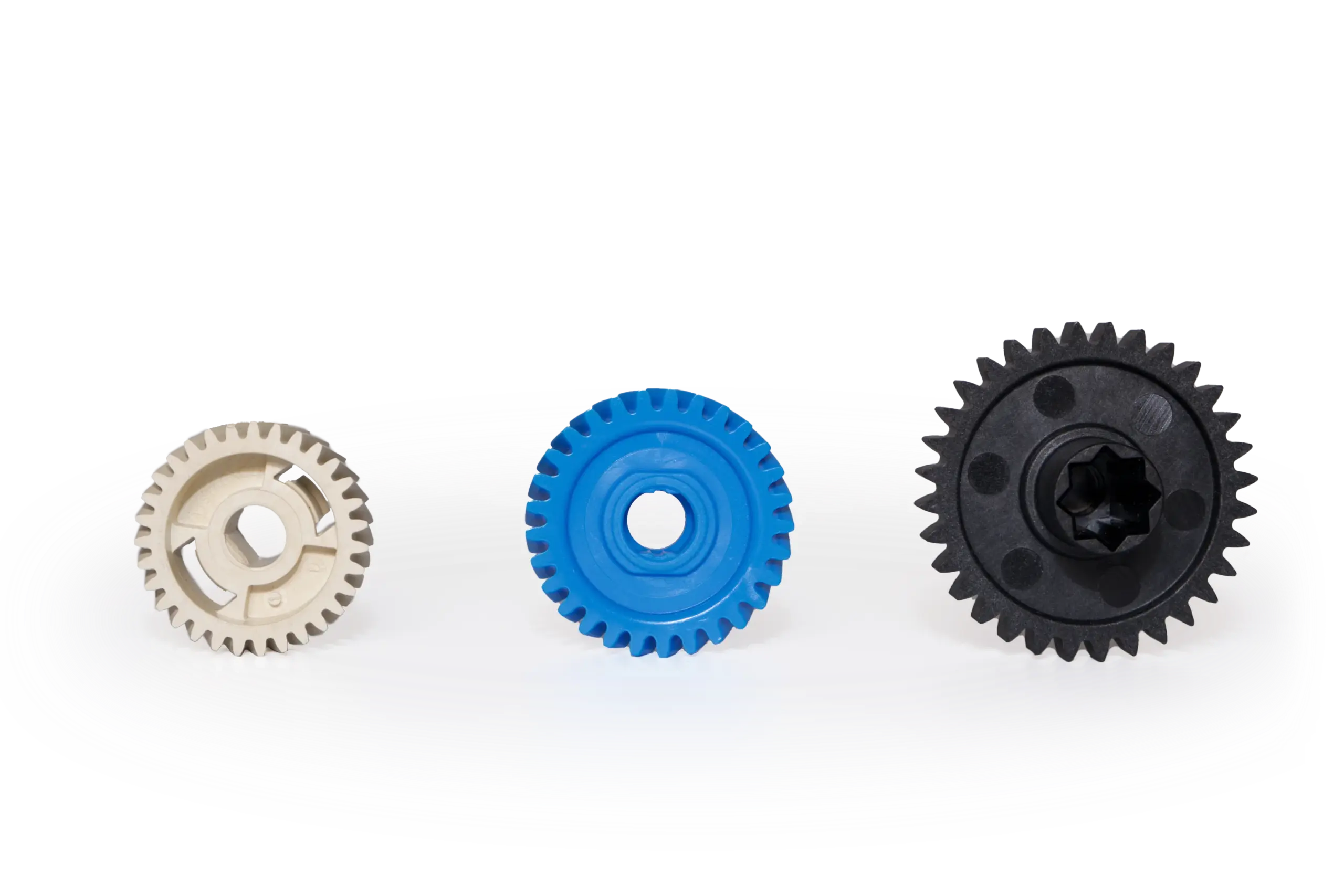

We shape motion with lightweight, durable and high-performance gears.

Stagnoli is your trusted partner in the design and manufacture of advanced plastic gears and transmission components.

From initial concept and prototyping to standard or fully customized production with high- precision injection molding, we support you through every phase of the project. Thanks to our deep industry expertise we turn your ideas into reliable, high-performance solutions built to the highest standards.

Manufacturing Expertise

With over 40 years of specialization in polymer gears and certified by ISO 9001 and IATF 16949, we deliver proven quality and reliability.

Cutting-Edge Technology

We specialize in injection molding of high-performance polymers and hyperpolymers, oSering technical support to help you choose the most suitable engineering plastic for your application.

Tailored Production

Explore a portfolio of over 3,600 standard catalogue products and more than 10,000 customised solutions, including metal replacement options to reduce weight and enhance mechanical performance.

Quality Assurance

We conduct over 40,000 quality checks annually, verified by detailed gear reports to ensure accuracy, durability and full compliance with technical standards.

Explore Our Catalogue

Browse over 3,600 plastic gear models designed for a wide range of industrial applications.

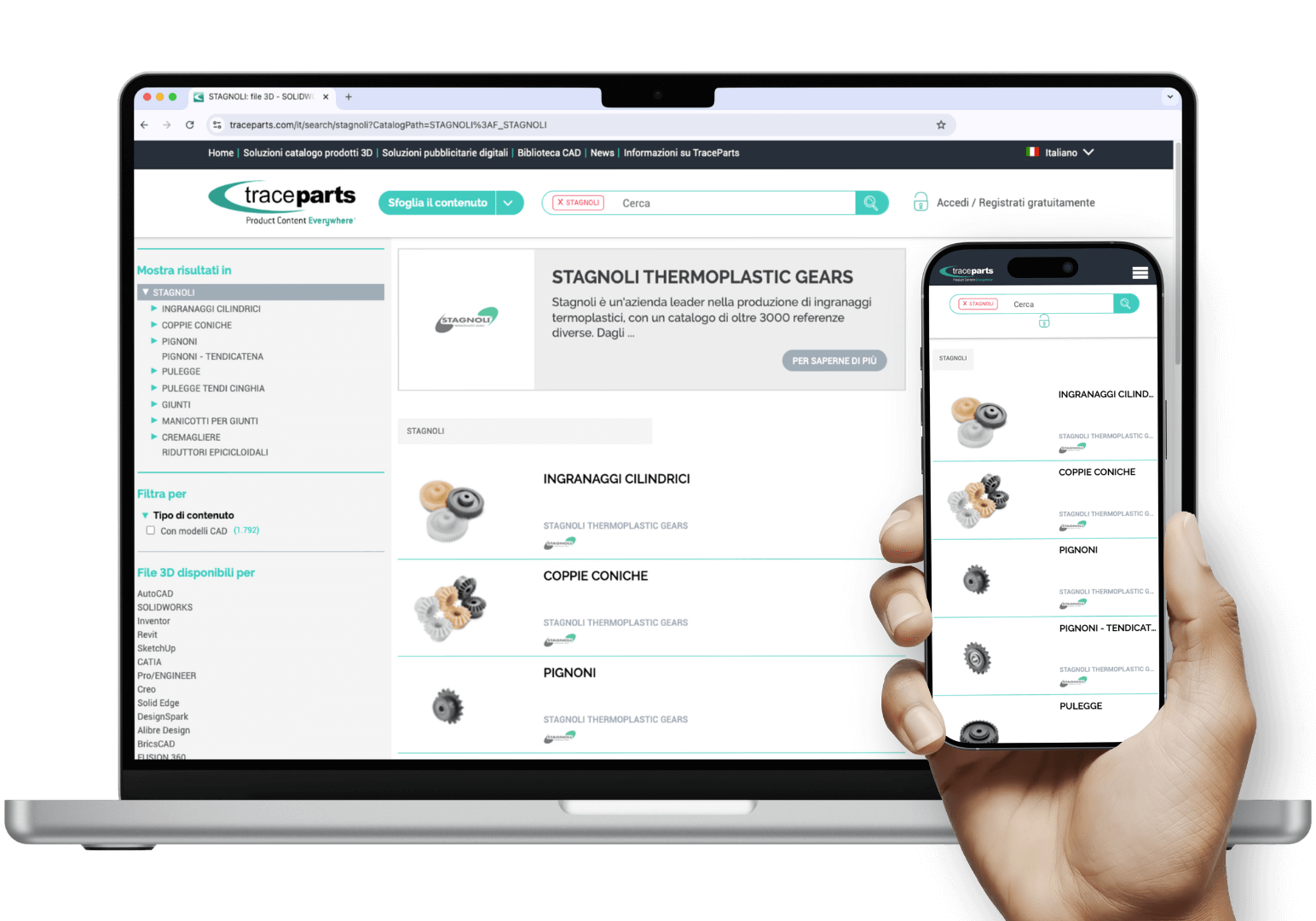

Ready-to-use 3D Models - Available on TraceParts

Our plastic gears are now even more accessible through TraceParts. Engineers and designers can quickly search, configure and download 3D models in just a few clicks. Enjoy full CAD compatibility, a multilingual interface and a continuously updated catalogue available 24/7 – designed to support every stage of your product development cycle.

Put Our Expertise to Work for You

Fill out the form to request more information—our team will get back to you promptly.

LATEST NEWS

30.06.2025

Stagnoli gears for the food industry: Hygiene, safety and certified performance

Read the article

05.06.2025

Gear quality control: a guide to reading measurement reports

Read the article

08.05.2025

Stagnoli is at IFFA 2025 with the new Spinyx gearbox: endless innovation

Read the article

26.03.2025

CAD models and 3D files of Stagnoli’s plastic gears are now available for free download!

Read the article