"FROM DESIGN TO PRODUCTION"

THROUGH PROTOTYPES AND MINI-SERIES

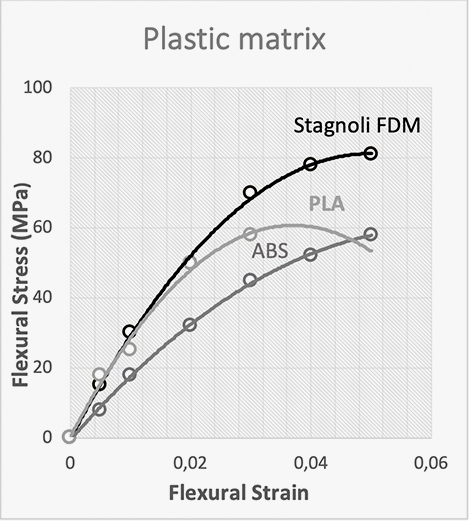

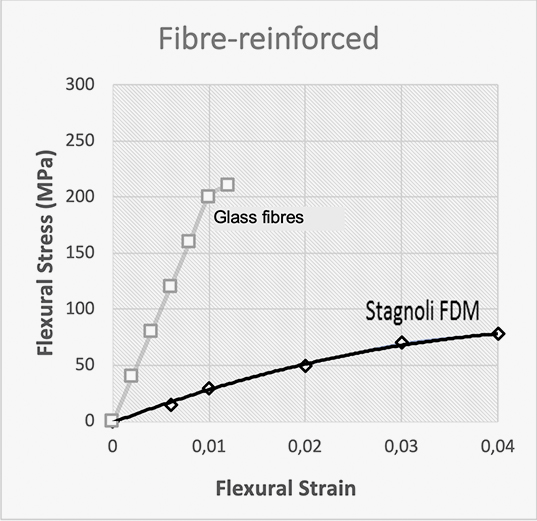

We provide a prototyping and micro-series production service, using a special FDM 3D Printing technology that guarantees high mechanical performance, up to 10 times higher than the plastics normally used in 3D printing thanks to the possibility of using also a fibre-reinforcement.

Characteristics

Our strong point is to provide a 3D printed technical component, with excellent mechanical properties, leaving the customer free to choose between two types of material, both having greater mechanical properties than the known PLA and ABS: Stagnoli FDM (polyamide based plastic matrix reinforced with chopped carbon fibres) or Stagnoli fibreglass FDM (in which Stagnoli FDM is further reinforced with glass fibres).

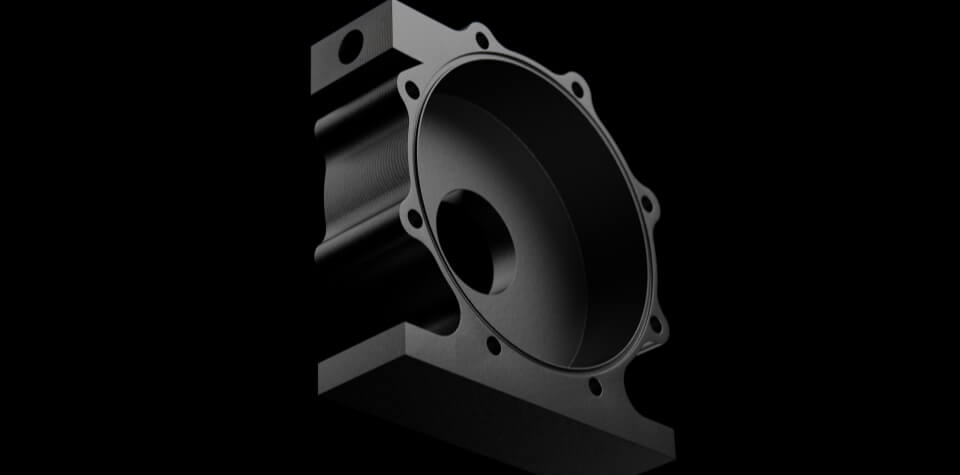

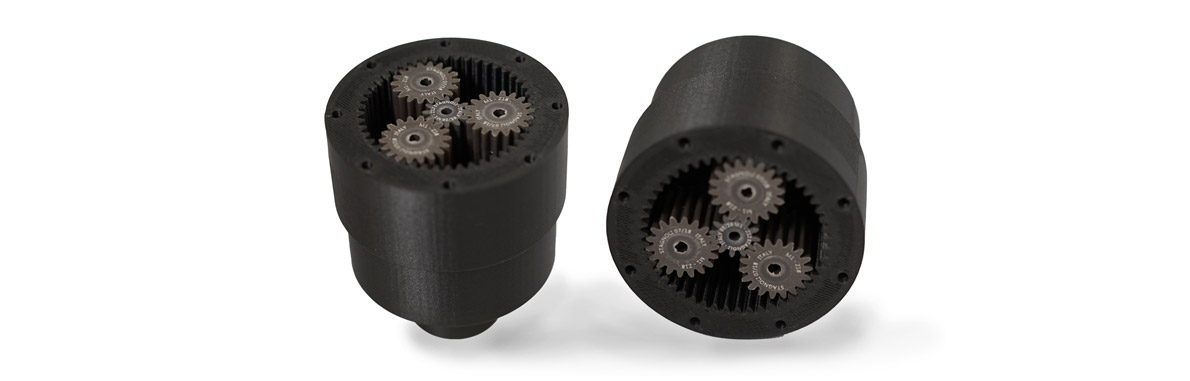

Our prototyping service is aimed at those who need precise and mechanically resistant structural components, such as gears, cases, support brackets and other components. The possibility of engineering the sample by reinforcing it only in the most stressed points or even on the whole piece is an advantage that few can offer.

ADVANTAGES

Thanks to this technology we are able to provide components suitable for life tests (duration), and comparable to injection moulded products.

This allows the customer to test the designed component in the actual application (whether it is a support, or a gear) and to proceed with the implementation of the mould, with greater safety.

Thanks to this step, the chances of having to modify the mould are also reduced, avoiding costly processes and shortening the time to launch the component on the market.

SPEED AND FLEXIBILITY

The production is fast, flexible and completely Made in Stagnoli, so we guarantee the delivery of small lots or single pieces in no time.

*Test samples have been designed to maximise test performance. The fibreglass specimens are completely reinforced with fibres arranged unidirectionally and moulded completely solid.All information provided by, or on behalf of Stagnoli, in relation to its products, whether as data, indications or otherwise, is supported

by research and in good faith deemed reliable.Stagnoli assumes no responsibility and does not provide any guarantee of any kind, explicit or implicit, including warranty of merchantability, fitness for particular purposes or non-violation, use or commercial practice in relation to the application, treatment or use of the aforementioned information or products.The user assumes all responsibility for the use of all the information provided and must verify the quality and other properties or all the consequences relating to the use of all this information.The values shown are indicative only and should not be interpreted as binding specifications.

Submit a project,

and we will build it together with you