Reducer and worm gears in plastic? Stagnoli goes beyond

31 January 2022

The helical toothed rotary mechanism – worm screw – is used in motion transmission between two orthogonal oblique shafts when a strong speed reduction is necessary of the driven shaft in limited dimensions. The screw is always driving, the wheel is always driven. Depending on the number of principles of the screw, the transmission ratio is obtained. For example, if the screw has a principle on each turn of the screw the wheel moves by a tooth. The screw gear is a strong speed reducer that overcomes great resistance with small power. The performance of this coupling is however low due to rubbing and therefore high wear. This definitely represents a weakness in metal materials.

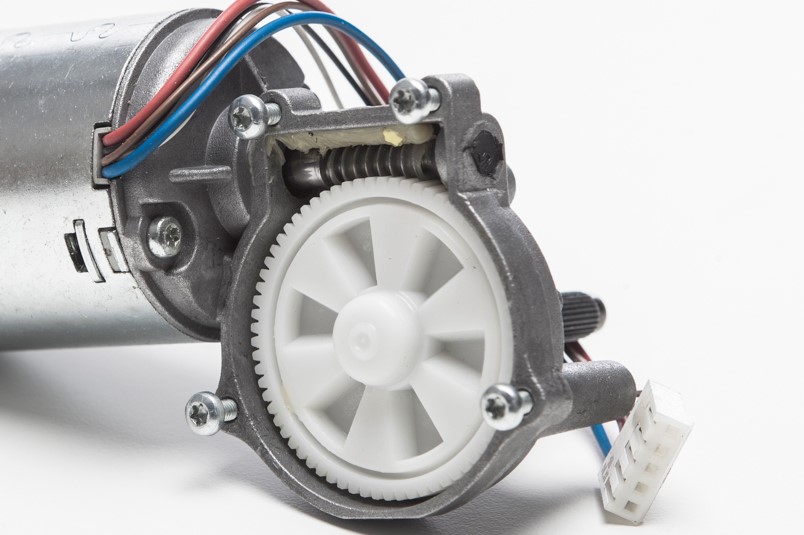

Plastic worm gears by Stagnoli Gears

This is the perfect context for our company, the leader in the design of gear reducers in technopolymer. Our experience and precision design of the geometry of the screw and the gear in plastic allow us to guarantee numerous solutions. The freedom of design granted by injection moulding has not only allowed us to replace brass and steel gears, but also research gears with geometries that are almost impossible to obtain with traditional materials. In many cases, teeth with special profiles have been optimised, corrected ad hoc to better balance the resistance of the transmission in the specific application in which it is inserted.

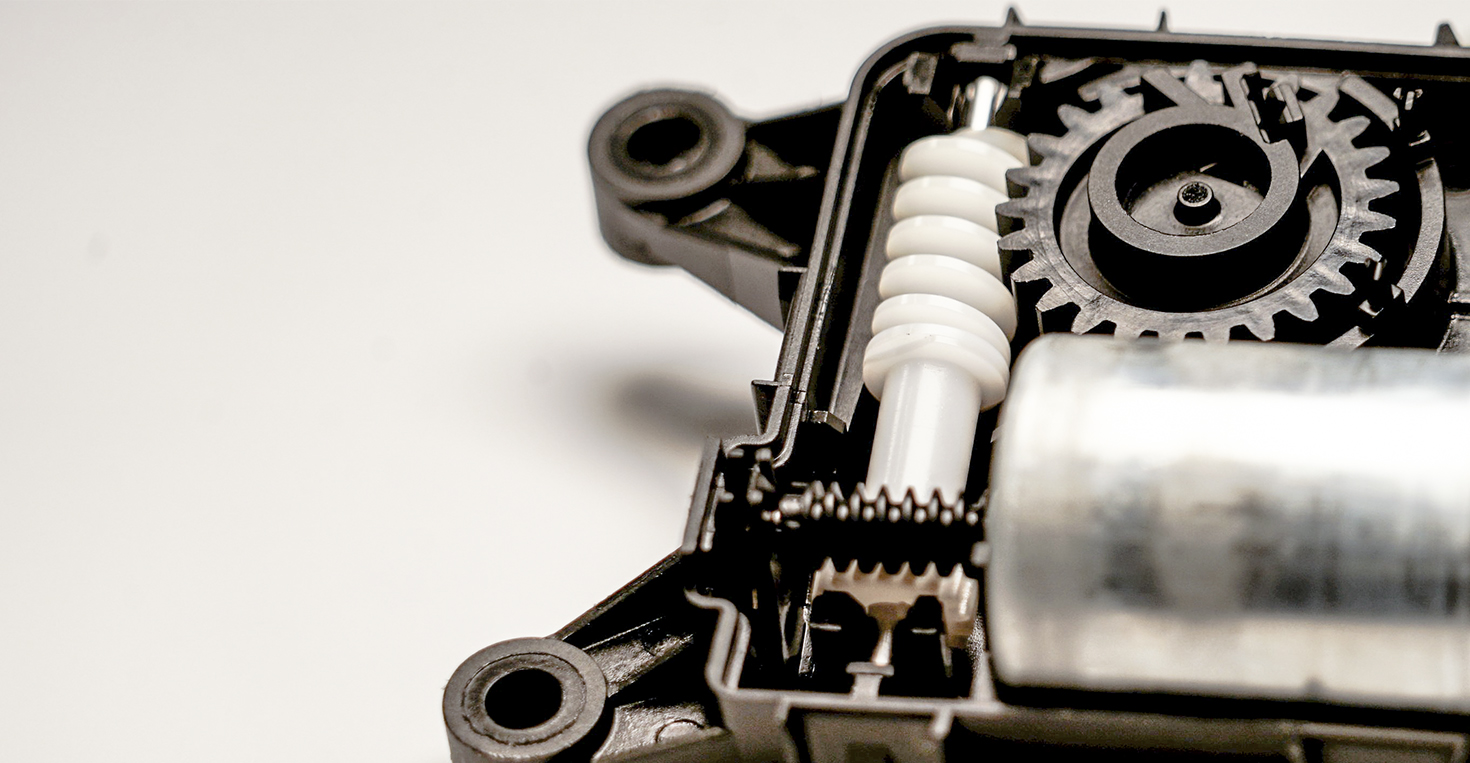

We didn’t stop there though. Receiving increasingly stimulating and competitive input from the market, we pushed ourselves even further: in recent months we have developed a double worm reducer in plastic for the automotive sector. There were multiple challenges:

- To determine a high level of precision for both worm screws to reduce power dissipation;

- Optimise the geometry to maintain such a performance to guarantee the necessary power for the application;

- Optimise the geometry of the teeth to reduce specific rubbing which would cause friction, and at the same time guarantee the feasibility of supporting the loads required by the application.

Yet again, the result was satisfactory and greatly repaid the effort made.

Do you want to develop a new project or you need consultancy to design worm screws and reducers in plastic? Contact Stagnoli Gears. Our staff are at your disposal.