Technopolymer mechanical components : what are they, what are they for and what advantages do they offer?

7 January 2020

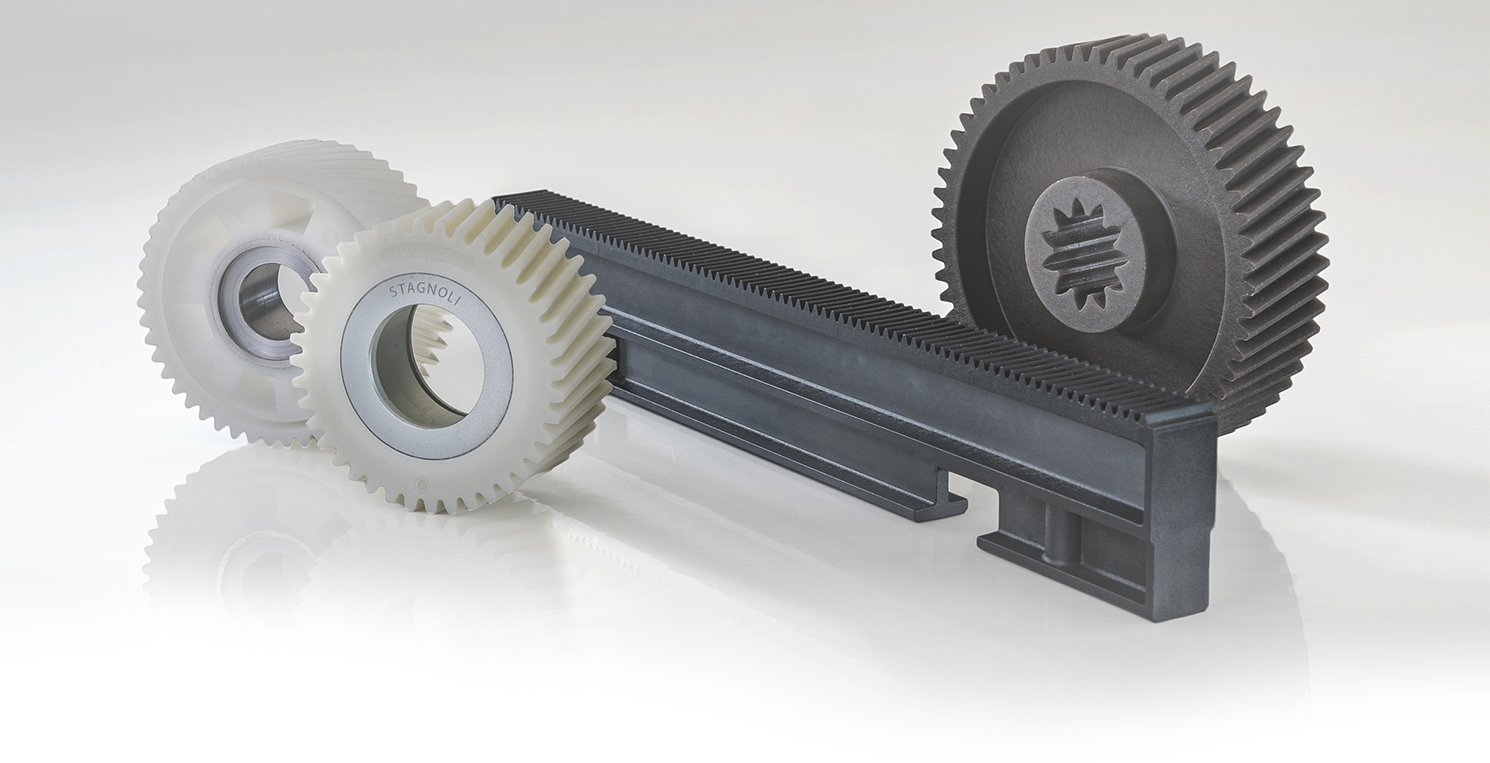

Technopolymer mechanical components are being used more and more and achieving greater success in various sectors, thanks to their innovative properties and the advantages they are able to offer. With its skill and professionalism, Stagnoli has committed to using technopolymers instead of aluminium or other alloys, offering its customers products in line with needs and able to offer high levels of performance.

What are these plastic materials? And what advantages are technopolymer mechanical componentsable to offer? We have decided to clarify and examine this topic in more depth in this article.

Technopolymers: what are they?

Technopolymers are not traditional "plastics" but materials with high thermal and mechanical performance, increasingly used instead of aluminium, base metals and other alloys. Polyesters, reinforced polyamides, acetal resins, polyphenylsulfones, polyetherketones, polyimides, polyamidimides and polyetherimides are all defined as technoploymers.

The main properties of technopolymers are:

- High elastic modulus

- High tensile strength

- Resistance to high temperatures

- Extreme lightness

Why should you choose technopolymer mechanical components?

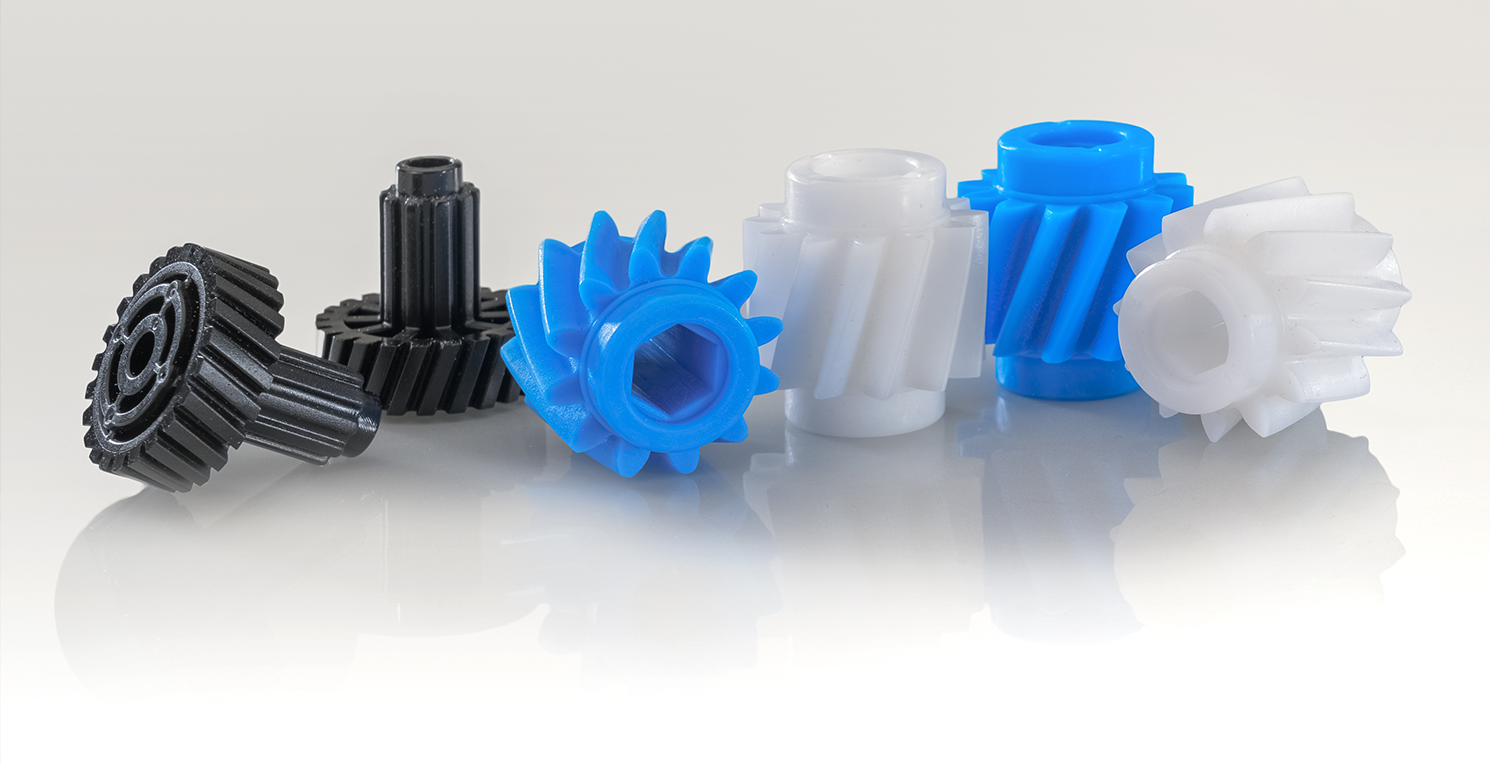

Today, technopolymers are increasingly used in mechanical components: making and using gears, pulleys, bushings, screws and objects built with these innovative plastic materials instead of die-cast aluminium or sintered metals allows us to achieve various objectives in terms of production but also performance. First of all,technopolymer mechanical components have a lower weight than products made of metal. Furthermore, they are made with a lower quantity of raw material and require shorter processing cycles, thus guaranteeing considerable savings. Technopolymer mechanical components are also more versatile than those made of aluminium, bronze and brass, and guarantee, in any application, the same performance, and in some cases even better performance.

In which sectors can technopolymer mechanical components be used?

Components and gears made of technopolymers can be used with maximum efficiency and with excellent performance in a range of different sectors. Here are some examples:

- In transport,technopolymer mechanical components are all those parts exposed to humidity, high temperatures, fluids or mechanical stress.

- The electrical sector takes advantage of the fluidity and good thermal resistance of technopolymers to make connectors, lamp holders, switches, coils and stator kits.

- Finally, in the manufacturing industry, technopolymer mechanical components are used such as gears, parts of electric motors and kinematic mechanisms, all traditionally and historically made of die-cast aluminium or sintered metals.

Looking for technopolymer mechanical components? Choose Stagnoli.

Stagnoli has extensive experience in the processing and production of technopolymer mechanical components. Stagnoli ensures its customers receive specialist know-how and maximum attention in design, offering components with high mechanical performance, with pinpoint dimensional accuracy.

For more information on technopolymner mechanical components please contact us: write to us here.