REDUCED NOISE WITH STAGNOLI PLASTIC GEARS

7 June 2021

NVH (Noise Vibrations Harshness) is gaining increasing importance, especially for gears working in sensitive environments such as measurement equipment or actuators in vehicles, where passenger comfort is priority.

In recent years, it has become increasingly important in the white goods sector (household appliances in general) given the choice of a single kitchen and living room ambient in recent residential construction is progressively gaining ground. Another significant reason for choosing quieter household appliances is to also use them during the night, which costs less, or when resting. To efficiently meet these needs, Stagnoli recommends its silent plastic gears.

Stagnoli’s contribution to noise reduction with its technopolymer gear

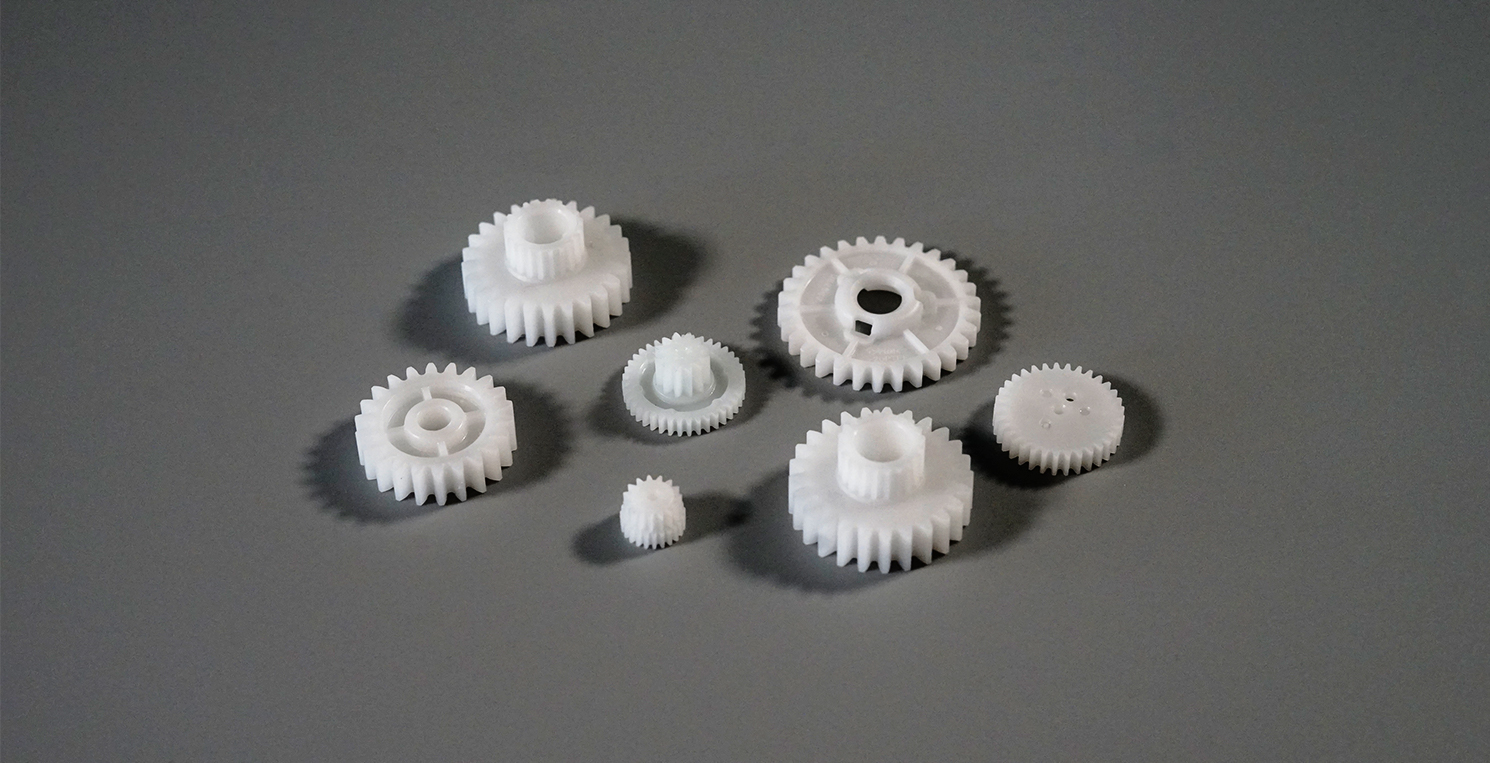

Stagnoli has greatly contributed to the growth of this sector and the request to reduce noise thanks to our know-how in the design and manufacture of plastic components. Our best contribution has been in the field of tecnopolymer gears, a sector where we are among the undisputed leaders.

Among the toothed wheels, in fact, the direction taken was without doubt to consider plastic materials, however what makes us stand out is the experience and know-how we have acquired in over forty years of business in the design and optimisation of the macro-geometry of teeth (module, helix angle, reference profile, profile movement and covering) and the micro-geometry of teeth. In fact, the main sources of noise in a pair of toothed wheels are:

- rigidness variations

- geometric errors

- surface rubbing

- knocks between gear teeth

Behaviour can be improved by applying profile changes.

Case study: noise reduction in the gears of a dishwasher

All these guidelines and know-how were applied in a recent case study where the client was complaining about the excessive noise in his application: a reducer with cascade of gears that activates automatic opening at the end of the cycle of the dishwasher door.

The redesign of the entire reducer and, in particular, all the geometric profiles of the gear teeth allowed us to overcome the challenge and reduce noise: tests conducted by the client have highlighted a 4-time reduction compared to the initial noise.

This, together with other case studies, has allowed us to gain exposure on some important magazines, the links to which are provided:

PLAST DESIGN MAY 2021 (sfogliami.it)

With 3D printing, quieter industrial gears! The case of Stagnoli T.G and Cmf Marelli - Industria Italiana

If you want to propose a project and/or you also have applications whose noise you want to reduce with silent gears, contact Stagnoli.