Home automation chooses Stagnoli: the new cascade gear reducers in technopolymer with worm screw

30 August 2021

Home automation is the science that deals with all computerised and electronic applications in the home. It is increasingly diffused in residential complexes, especially new constructions and renovations.

Thanks to automation, windows, sliding and rotating doors, curtains, shutters and gates can be controlled, opened, closed or adjusted using electronic control systems and electric actuators, often called motors for windows designed for automatic opening and closure of door and window fixtures in residential areas.

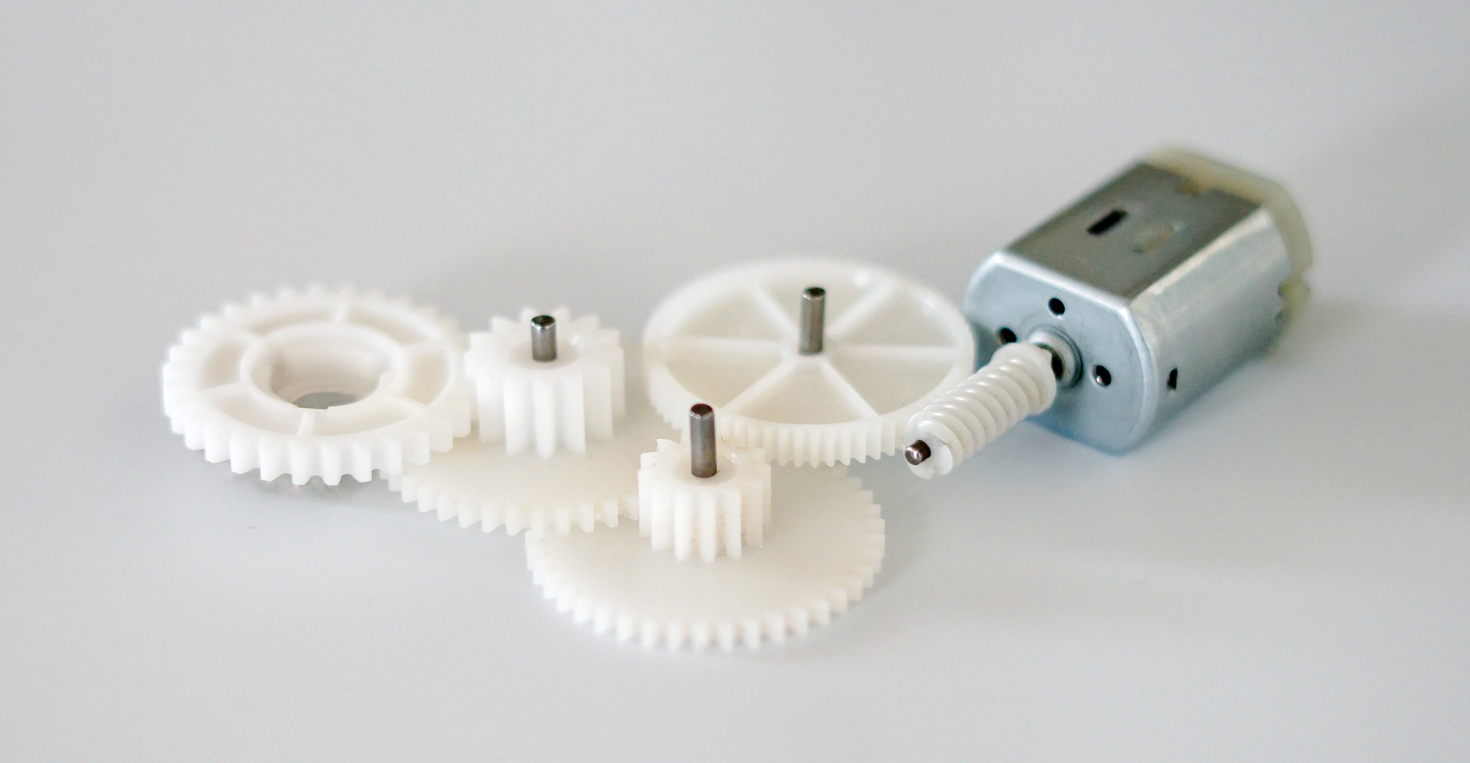

Cascade gear reducers in technopolymer by Stagnoli

In this context and these surroundings, Stagnoli also offers innovative solutions. Our company is the leader in the design of gear reducers in technopolymer.

The most requested for home automation include cascade gear reducers in technopolymer with worm screw that perfectly meet the specific design and construction needs of silent and light systems.

Stagnoli, always in search of new technologies and improvements for its production, presents a preview of the project that involved construction of a cascade gear reducer in technopolymer, a product dedicated to home automation and door and window opening.

The entire system includes a plastic worm screw and was designed and optimised in technopolymer thanks to the know-how and professional skills of our technicians. Different mechanical strength analyses were carried out following VDI2739 guidelines. Furthermore, use of KissSoft software allowed optimisation of the gear teeth with corrections and measures to increase its coverage, strength and wear and at the base of the tooth.

Cascade gear reducers in technopolymer by Stagnoli use top quality materials and the geometries of the teeth were designed in every detail, taking into account the needs for silence and the power necessary.

Fundamental objectives in the manufacture of the reducer were to:

- Minimise dimensions;

- Obtain maximum compactness of the entire reducer;

- Maximise silence;

- Guarantee an endless life cycle of the gears.

During the test phase, the entire application achieved excellent results and cascade gear reducers in technopolymer came into production in September 2021.

For further information on cascade gear reducers in technopolymer by Stagnoli, contact us. Our staff are at your disposal.

NEXT NEWS

21 July 2021