CFRP: carbon-fiber-reinforced plastic materials

11 March 2019

CFRP: carbon-fiber-reinforced plastic materials

For the past 15 years our company is constantly looking for improvements and innovations in order to offer its customers various solutions according to their needs. The flagship of our range of products is the production of CFRP gears and components, abbreviation that indicates the gears and components produced with carbon-fiber-reinforced composite materials.

Today, in the mechanical engineering sector, metals are replaced with plastic composite materials as these are able to offer practical solutions where traditional materials fail. In fact, the production of CFRP gears allows solving problems related to the operation of the machines both at a thermal and mechanical level, with significant savings in terms of weight.

The properties of cfrp gears and components

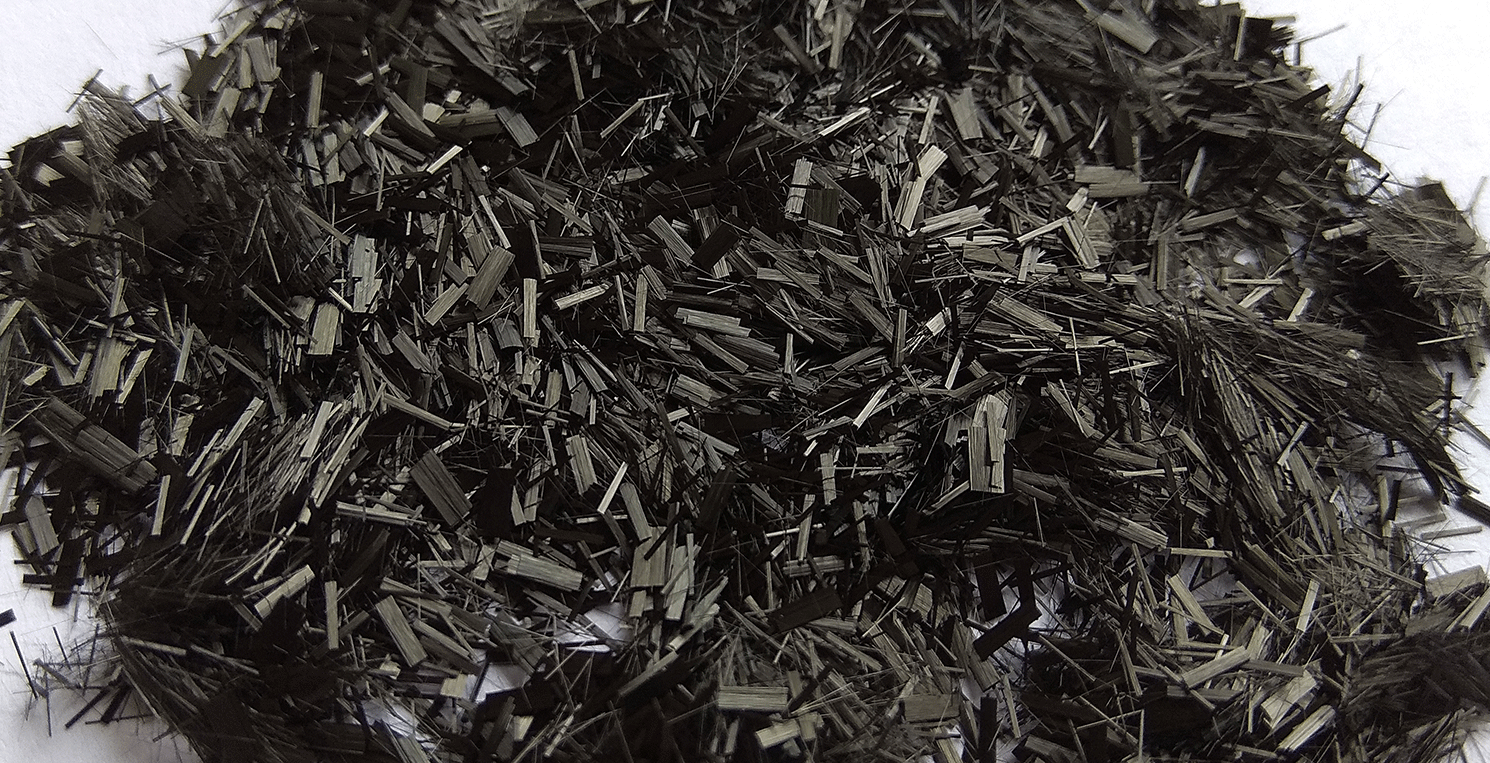

The properties of carbon fibers make the carbon-fiber-reinforced composite materials ideal for many applications. In fact these fibers not only have a low weight, but at the same time have a high modulus of elasticity and low thermal expansion thanks to their composition.

Use of carbon-fiber-reinforced plastic gears

These features allow carbon-fiber-reinforced plastic gears to be used in different application sectors such as robotics, or aerospace and medical industries. On what concerns the industrial sectors, these materials are highly used both in the production of machine tools and in the automotive sector; each application may require specific material, which may vary both for the polymeric base (PA6-PA66-PPA etc.) and for the fibers (Long, Short, etc.), but also for the presence or absence of PTFE or molybdenum Sulphide.

The gears and components made of carbon-fiber-reinforced composite material are an excellent choice also for their self-lubricating properties. These features extend the life cycle and save time for production.

The experience that our company has gained in this field allows us today to have a history of successful applications in order to be able to replicate safely, and to size the best thickness and layout of toothed wheels or racks.

Contact us for further information on the production of CFRP composite components.