Gear quality control: a guide to reading measurement reports

5 June 2025

Gear quality control is an essential step to ensure that each part performs its function perfectly. To achieve this, some key geometric parameters that directly influence performance are analysed very carefully, such as tooth profile, pitch and radial runout. Measurement is performed using advanced precision instruments, which are an integral part of modern gear metrology technology and able to measure data with micrometric resolution.

During the process, each tooth is examined on both sides—left and right—and the values collected are included in an accurate gear metrology report, which is a technical summary of the inspection performed.

The main parameters assessed include:

- Pressure angle (α): defines the inclination of the contact forces between the teeth, influencing the efficiency and robustness of the gear.

- Single pitch deviation: measures the error between the actual and theoretical pitch between two consecutive teeth, highlighting any defects in spacing.

- Radial runout: indicates the deviation of the real axis of rotation from the centre of the primitive circumference; a crucial parameter in the gear measurement report.

- Angle and shape of the helix line: these describe the geometry of the helix path, the consistency of which is decisive in reducing vibration and noise in coupled operation.

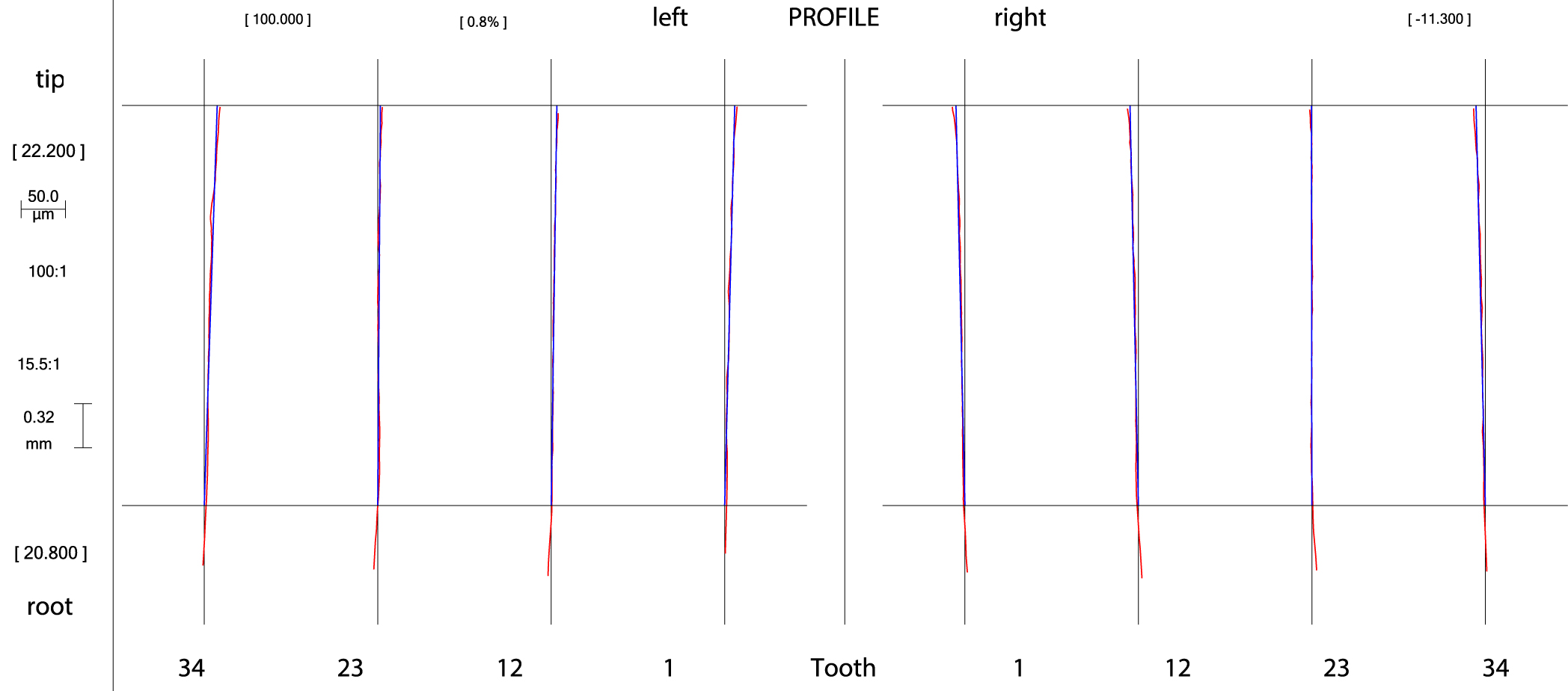

The metrology report can include both numerical tables and intuitive graphics. In graphs, the ideal profile curve is generally a continuous line (often blue), while the measured curve appears dashed or in a different colour. This makes it possible to visually capture local deformations, shape errors and unforeseen variations.

This graphical representation allows any anomalies such as local deformations, shape errors or unforeseen variations to be detected immediately, facilitating the technical dialogue between manufacturer and customer.

It is important to remember that not all deviations have the same functional impact. For example, a slight error on the propeller angle may be negligible in some applications, but decisive in high-speed systems. That is why a correct interpretation of the gear metrology report requires technical expertise and a clear understanding of the context of use.

In conclusion, gear metrology and measurement reports are not mere verification documents, but fundamental tools in ensuring component quality, reliability and durability, and in defining effective continuous improvement strategies.

For more information, CONTACT US.