Planetary gears in technopolymer: the planetary challenge by Stagnoli

29 March 2021

Stagnoli is a leader in the design and manufacture of transmission elements, gears and gearboxes entirely made of technopolymer. The experience and know-how acquired in over thirty years of design and manufacture of the latter mean the company is considered an innovative partner for important, international projects in the metal replacement sector.

Stagnoli, a guarantee in the plastic gears market

The high precision with which our products are made and the numerous benefits of using more suitable technopolymer have enabled Stagnoli to enter the gears, linear actuators and electric motors sector. Always more frequently, the Lonato-based company supports manufacturers of this market in the design and manufacture of product lines with plastic gears.

Some examples follow of technopolymer gears we design and manufacture:

- worm gears

- helical cascade gears

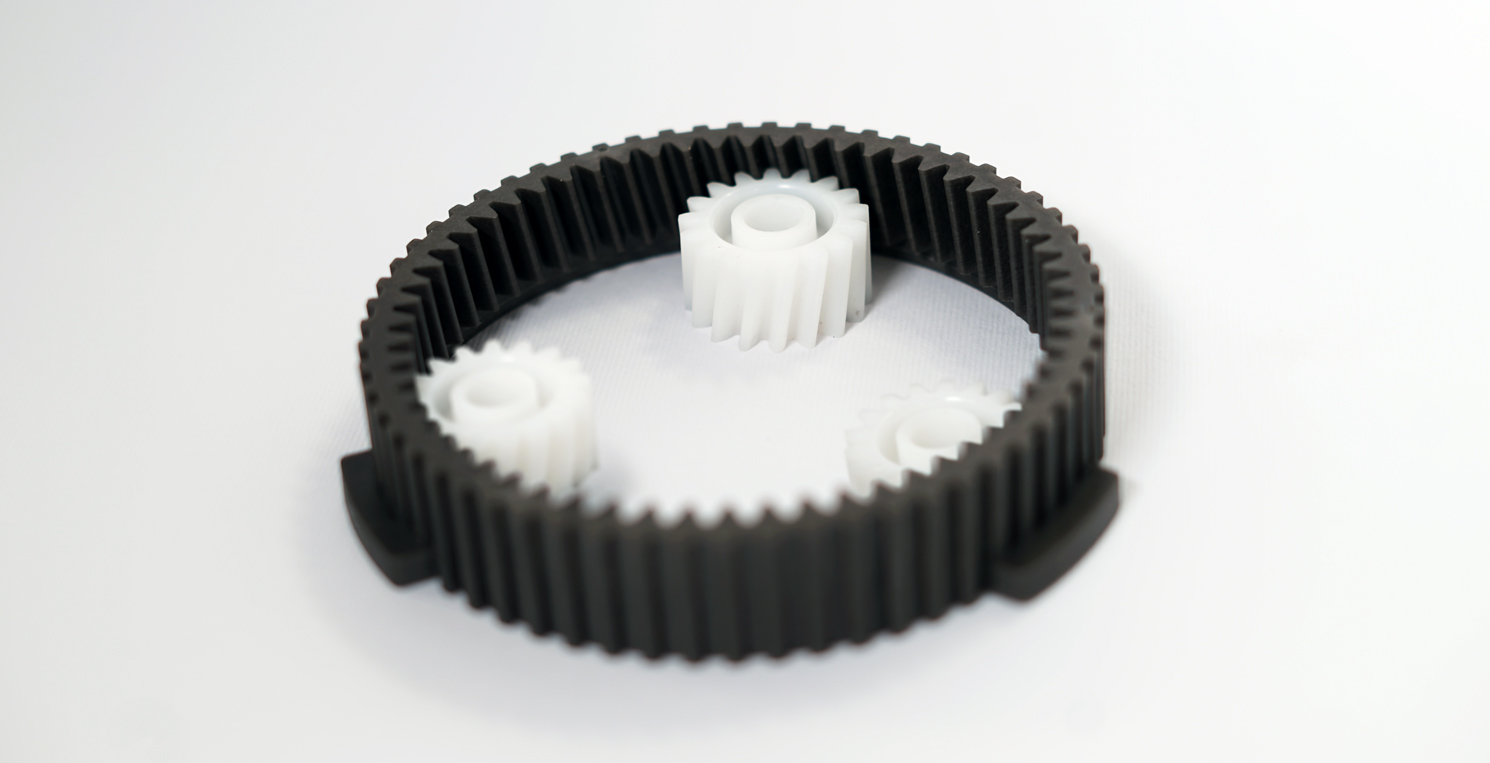

- planetary gears

Thanks to the absence of lubrication and the freedom of design granted by injection moulding, Stagnoli managed not only to replace brass and steel gears, but also research gears with geometries that are almost impossible to obtain with traditional materials. In many cases, the cogs with special profiles have been optimised and adjusted ad hoc to better balance resistance of the transmission in the specific application for its insertion.

Stagnoli has overcome the challenge of planetary gears

Until recently, the challenge lay in design and optimisation of planetary gears. Let's take a closer look at what was involved.

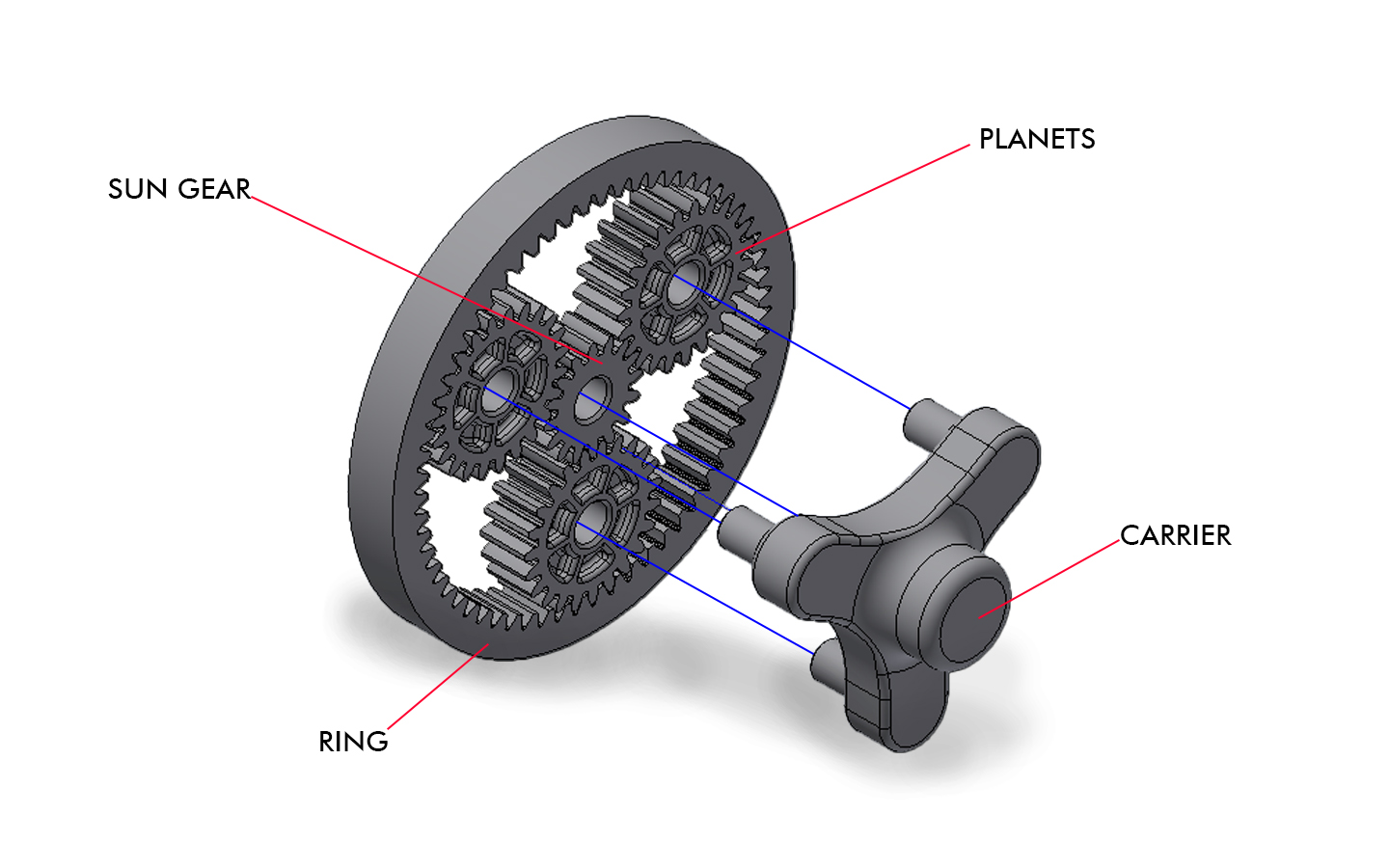

Planetary gears on the engine shaft have a pinion fitted called the sun, found at the centre of the gear and which transmits movement to other “planets or satellites”; these are fixed, using pins, to a satellite holder and rotate inside a toothed rim gear placed on the external surface of the gear. The number of gear holders represent the stages of the gear. The last gear holder is connected to the output shaft.

The advantages of Stagnoli plastic gears in metal replacement

Use of planetary gears, and in particular planetary gears in plastic, gives benefits that these components offer in certain applications:

- The high reduction ratio which, if compared to similar technologies, allows high performance to be reached;

- a more compact and at the same time light system (the specific weight of the plastic is almost six times less than that of steel): this means a lighter component and therefore the entire application which reflects in performance, as well as consumption;

- a more silent system: the intrinsic nature of the technopolymer and plastic in general allows reduced noise and lower vibration transmissions;

- a self-lubricating system: the molecular structure of the polymers guarantees a coefficient of friction and wear that is so low it makes lubrication pointless in some cases;

- a chemically inert system: plastic is inert against most aggressive chemical agents and aqueous substances that cause wear phenomena and corrosion of metal elements.

Stagnoli’s strength in design and manufacture of plastic planetary gears

Stagnoli’s strength lies in its successful designs. In the first quarter of this year, it overcame another challenge by reworking the design of its planetary gear which had a loud noise issue in a food and beverage sector application.

The design involved Stagnoli’s indispensable know-how in the choice of cog geometry and the optimisation and structural analysis of the latter according to VDI2736 which has now become the international standard of the mechanical industry for plastic gears. Additionally, for years, Stagnoli has been the first of its kind to produce cyclic fatigue testing on its gears. The mix of data deriving from the design with VDI2736 with those of our internal tests allowed a useful life estimate for each type of gear and give a guaranteed answer on application feasibility. In this specific case, the result was fully satisfactory since the noise was reduced compared to the application by a competitor company. It was 10 dB (meaning the application became 10 times less noisy than the previous one).

Do not hesitate to contact us for clarifications or if you want to propose a new design and a new challenge. Contact us.

NEXT NEWS

2 March 2021